Design

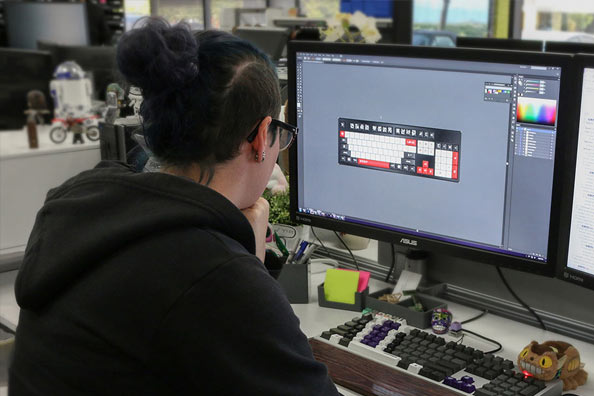

The first stop on your order's build process journey begins in the digital realm before even touching any keyboards or keycaps. We take your carefully selected colors and layout design choices from our online designer and convert them to a format that plays nice with our UV printers.

Keycaps

Next we pull up a digital layout map of your order and start pulling the keycaps to populate our special keycap trays according to your custom color choices. After a layout is completed we arrange the keycaps, then finally cross reference the colors one more time for accuracy.

This is where the magic happens; we pop the tray into our UV printers like a fantastical mechanical pizza with all the fixings. Special care is involved when printing your layout, we double check print consistency, color quality and ink saturation. Any errors or defects that may occur during printing are reviewed and resolved before any further steps are taken.

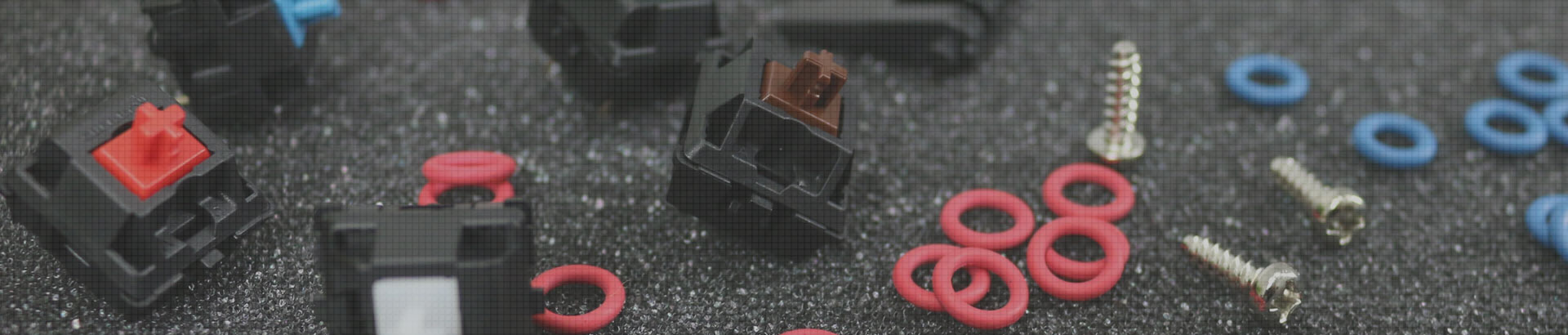

Assembly

Freshly printed keycaps are ready to handle thanks to the ultra fast curing time of our UV printers, we tackle the large keys with stabilizers first and we carefully lubricate all mating surfaces. After actuating and testing all stabilizers, we ensure there are no squeaks, rattles or binding through the full operation of the switches.

Quality Assurance

Here we go through a 10 point checklist on each keyboard, double (and often triple) checking to make sure everything on the order is correct. We offer a massive amount of options and customization and it's very easy to make mistakes so this step is very important in making sure all of the decisions you have made end up correct on your order.

Shipping

Finally your order is ready to make its voyage to your doorstep, we pack each of our custom made keyboard shipping boxes with care so that your order happily and comfortably reaches you.